One of the most expensive upfront costs for a farmer is farm equipment and machinery. From combine harvesters to sprayers, cultivators to planters, it’s easy to rack up thousands of pounds buying all the agricultural machinery you need to run a successful business. A new tractor on its own, for example, costs upwards of £8,000.

Unfortunately, these costs are only likely to increase over time, with the Office for National Statistics (ONS) reporting that machinery prices jumped by 80 per cent in just ten years. It is thought that this is down to emissions regulations, which are expected to get stricter as climate change continues to be a threat.

Considering the amount you’ve spent on farm machinery, you will no doubt want to make sure you look after it properly. With that in mind, we’ve written this article, which explains everything you need to know about maintaining your farm equipment and machinery.

What type of farm equipment and machinery needs to be maintained?

Some of the equipment that needs maintaining on a farm includes tractors, combine harvesters, ploughs, cultivators, manure spreaders, planters, seed drills, sprayers, mixer wagons, dispensers, balers and tools.

This is not an exhaustive list, however, and the equipment and machinery that needs to be maintained on a farm depend on the type of estate you run and how big it is.

Continue reading to find out how to care for your agricultural equipment properly.

Why do I need to maintain my farm equipment?

Maintaining your farming equipment may seem like an extra hassle that you just don’t have time for, but it is important to do so for several reasons:

- Performance — By maintaining your equipment and machinery, you can ensure it is working to its full potential, saving you not only precious time but money on repairs.

- Longevity — Caring for your equipment properly can extend its lifespan. This means you won’t need to replace it as regularly, which will save you money.

- Safety — Well-looked-after equipment is less likely to malfunction and cause injury to the operator.

- Quality — Calibrating equipment like thermometers, sensors and metal detectors can ensure the quality of end products.

- Insurance — Looking after your machinery and equipment can lower your premium. If your insurer knows, for example, that your equipment is being stored out of the elements, they will view it as less of a risk as it is less likely to need to be repaired or replaced.

Imagine one of your machines breaks down, and you are waiting for it to get repaired or replaced. Every moment spent waiting is costing you time and money. Farming processes like seeding and harvesting have strict timelines, and the machinery used to carry them out must be ready on time — otherwise, there could be serious losses. Maintaining your equipment can prevent you from being in this situation.

Maintenance is especially important in unfavourable conditions, like bad weather, humidity, uneven ground and excessive dust, as this can put more strain on it and cause it to break down.

Who performs agricultural equipment maintenance?

It is usually farmer owners themselves who are responsible for maintaining equipment and machinery — especially on family-run farms and smallholdings. This means you need to have a full understanding of how everything works, how it should be cared for and how often maintenance needs to be carried out.

How to perform maintenance safely

While it is important to maintain your farm equipment, it is just as important to carry out the maintenance safely.

Before you begin any farm equipment maintenance, it is wise to take the following steps:

- Seek training — The best way to prevent injury or damage is to get some formal training in agricultural maintenance.

- Add appropriate signage — Hazard signs in areas with fumes, excess dust particles and fragile flooring can help workers exercise caution to prevent them from injury while carrying out maintenance work.

- Plan maintenance tasks in advance — Scheduling maintenance work at regular intervals helps prevent unplanned maintenance that occurs as the result of a machine breaking down. When planning when to carry out maintenance work, you need to take into account things like how often the machines are used and at what time of year, what their job is and how much demand is put on them.

- Read the owner’s manual — In order to properly maintain your equipment, it is advisable to read the owner’s manual. It will tell you how to perform routine maintenance tasks and advise on any hazards that might be present during maintenance.

- Shut down the equipment — To stop the machine from powering on during maintenance and risking possible injury, make sure it has been properly shut down and secured. As well as turning off switches, disconnect all power to the machine.

- Use adequate Personal Protective Equipment (PPE) — Most mechanical maintenance work requires hard hats and gloves. Hard hats are also a must when working at a height, in addition to fall-prevention equipment. If you are working in a confined area with fumes or excessive dust, you will need to wear a mask or respirator.

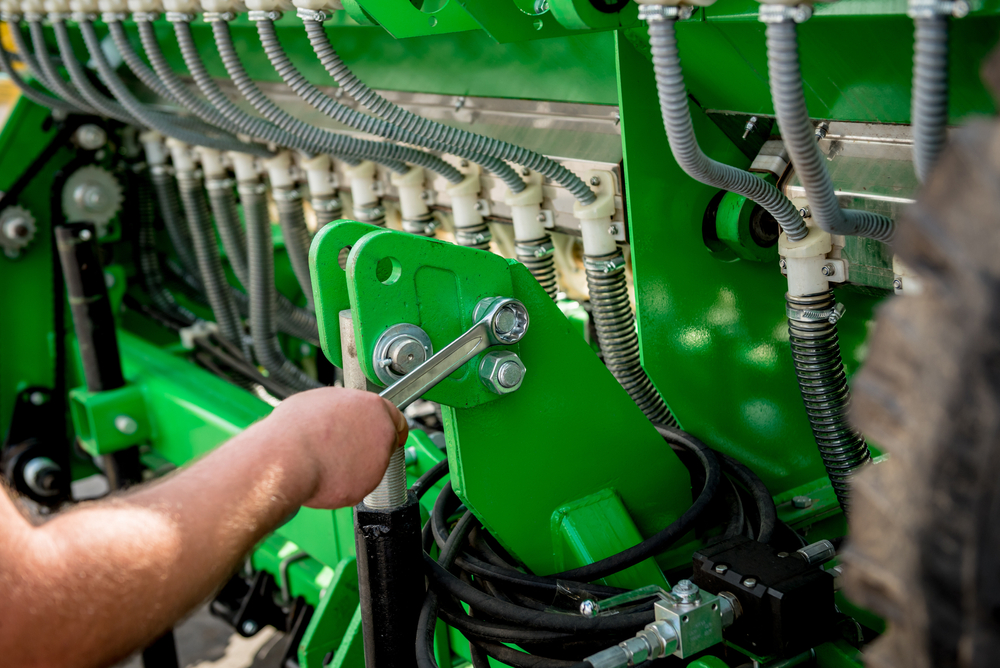

- Use the right tools — To prevent injuries caused by using the wrong tools (or ones that are poorly designed), ensure the correct, adequate tool is readily available for the maintenance job you are doing.

- Avoid cross-contamination — When maintaining equipment that has come into contact with hazardous substances (such as cleaning products and pesticides), take thorough precautions to prevent cross-contamination with food and other chemicals.

10 tips for maintaining your farm equipment

Here are ten top tips for ensuring your equipment is properly maintained:

1. Day-to-day checks

To keep your machinery, tools and equipment in good condition, it’s important to look after them on a day-to-day basis. This means using them in the correct manner, and for the purpose they are intended, adhering to the advice given in the owner’s manual, avoiding putting them under excessive strain and storing them in a dry, well-ventilated, sheltered place.

The person operating the equipment should look out for the following signs and alert their superior if they spot any of them:

- Electrical system faults

- Temperature above range

- Tyre pressure or condition diminishing

- Unusual engine sound

In addition to daily checks, the person responsible for maintenance should perform routine checks for things like spark plugs, batteries, brake and signal lights, trailer hitches and tyres (including spares).

If a piece of machinery isn’t used on a daily basis, it is a good idea to start the engine weekly and activate the hydraulic circuit. This is to prevent oxidation and encrustation.

2. Clean regularly

Cleaning is one of the best ways to preserve the life of your farm machinery. Without regular cleaning, dirt, grain and other sediments can build up and clog filters, increase fuel consumption and cause damage to other parts.

Simple cleaning tasks, like hosing down machinery and removing leaves and hay, can be done daily, while deep-cleaning using specific detergents or compressed air should be done at regular intervals or in extreme cases. Cleaning your equipment is especially important at the end of a season before you store it.

3. Check and change fluids

Like cars, the oil level in farm vehicles and machinery needs to be checked and changed on a regular basis.

As well as checking the oil level daily and performing regular oil changes, the other types of fluids that farmers need to check on are:

- Transmission fluid

- Coolants

- Hydraulic fluid

Transmission fluid and coolants should be checked daily, while hydraulic fluid needs checking every couple of years.

Because you likely have multiple vehicles and machines to check, it is a good idea to keep a record of all fluid changes so you know when to schedule the next ones.

4. Keep moving parts lubricated

Lubrication is key to ensuring your farming equipment stays in good working order. All moving parts on your equipment need to be greased regularly. How regularly will depend on how often you use the equipment and the manufacturer’s guidelines, as well as your climate conditions. In extremely wet weather, for example, you will need to lubricate your machinery more frequently.

5. Check and change filters

Agricultural machinery needs filters to clean contaminants out of fluids like lubricants and fuel.

Filters should be changed according to the manufacturer’s instructions. However, as a guide, oil filters are typically replaced at the same time as an oil change. Depending on usage, this is roughly once every 100 hours.

Air filters may need replacing much more frequently than this, though. It is best to check them daily and change them whenever they get clogged.

6. Examine bearings

Ball bearings are used to ensure anything that rotates — such as the rollers on a conveyor belt or the wheels on a tractor — does so smoothly.

However, over time they wear down, so it’s essential to check them regularly. Again, how regularly you perform your checks depends on how often you use the equipment, your climate conditions and what the manufacturer recommends.

In addition to your regular checks, you will know that your bearings need replacing if your rotating equipment starts to overheat or you hear grinding noises.

7. Calibrate equipment

Devices that use specialised equipment like thermometers, thermostats, scales or metal detectors need to be checked and recalibrated regularly. If the calibration is off, it can lead to inaccuracies and health and safety issues.

Calibration should be done according to the guidance given by the manufacturer.

8. Maintain tools

When carrying out maintenance on your farm, remember to include your tools.

Sharpening shovels and forks before and after you use them will not only make digging easier, but they will be less likely to break. Wooden handles should be checked for the same reasons.

Any metal parts can also be greased to prevent rust.

As with machinery, it’s recommended that you clean your tools after each use and store them in a dry, sheltered place.

9. Check for damages

Even with the best care, parts can wear out over time. So it’s good to get into the habit of inspecting your equipment for signs of damage on a regular basis — or at least every time you put it into storage.

Some of the things to look out for include:

- Cosmetic damage that could be concealing more serious problems

- Leaks in hoses, cylinders, fuel lines and hydraulic lines

- Loose or broken pieces

- Loose tension on belts and chains

- Strange noises

- Strange odours

10. Winterise

The cold weather puts farm machinery and equipment under more pressure. Farmers typically get their equipment ready for the winter months by carrying out the following tasks:

- Checking antifreeze levels

- Cleaning and oiling equipment that’s not needed during winter and putting it into storage

- Disconnecting the batteries of stored machinery (or keeping them on charge)

- Making outstanding repairs

Summary

Maintaining farming equipment like combine harvesters, ploughs, planters, mixer wagons, and balers may seem like an extra hassle, but it is important to do so for several reasons. It ensures that the equipment is working to its full potential, it extends its lifespan, it means it is less likely to malfunction and cause injury, it ensures the quality of end products, and it can lower your insurance premium.

Maintenance is especially important in unfavourable conditions, like bad weather, humidity, uneven ground and excessive dust, as this can put more strain on it and cause it to break down.

You can ensure proper maintenance of your farming equipment by:

- Carrying out daily checks

- Cleaning it regularly

- Checking and changing fluids

- Keeping moving parts lubricated

- Checking and changing filters

- Examining bearings

- Calibrating equipment

- Maintaining tools

- Checking for damages

- Winterising it

Also read:

What are the different types of tractor used in agriculture?

What size tractor do I need?

Eight ways to protect your farm from fuel theft

Top 9 uses of wool